How Investment Banker Chris Yerolemou Pivoted to Bespoke Millwork

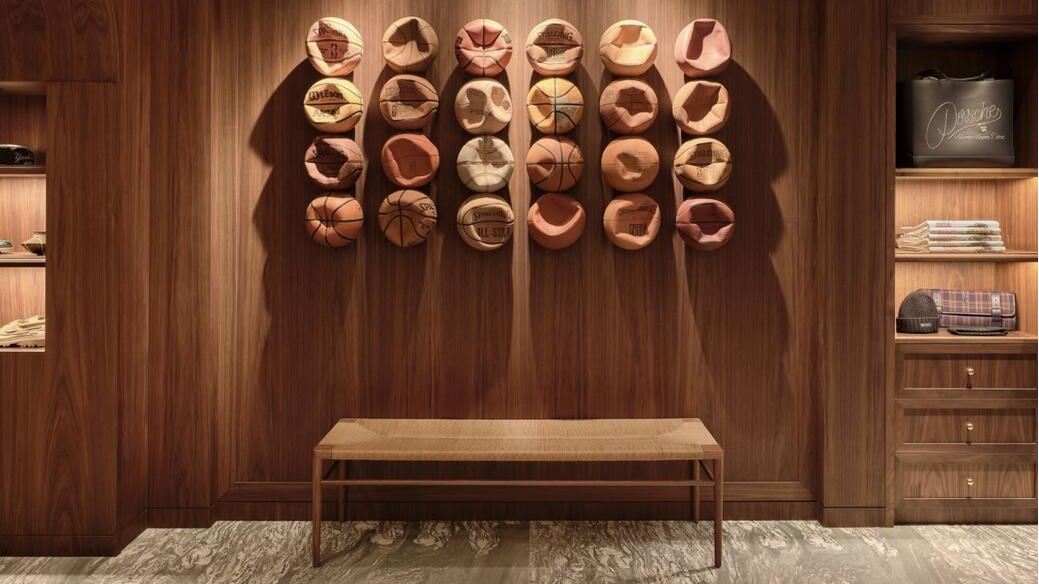

Axos millwork featured at the SoHo, NYC, boutique of streetwear brand Aimé Leon Dore

Going from investment banking to millwork might seem like an unusual career path, but it's one that came naturally to Chris Yerolemou. In fact, it's in his blood. His father, Tasos Yerolemou, was a master craftsman, who operated a small company in NYC and "knew how to build some of the nicest pieces in New York," his son says. Seven years ago, when the popular Greek restaurant Avra came calling for his father to create millwork for a Beverly Hills location seven years ago, Chris stepped in to assist with project management and logistics—and that was the critical inflection point for the company.

Since rebranding as Axos Designs, the family-run millworking company has delivered exquisite craftsmanship in commercial locations like Kith Ivy, Aime Leon Dore, and the Crane Club. Using their signature surface treatments along with custom stains, burnishings, and metal/wood blends, Axos Designs is also exploring more residential work, as well as opening a new 30,000-square-foot factory in Long Island City, New York.

We spoke with Chris about what it's like taking over the family business and how they continue to grow while offering the same service and quality goods. (This interview has been edited and condensed for clarity.)

Axos Designs millwork featured at the Giorgio Armani-branded spa at Kith Ivy, a luxury members-only lifestyle brand and exclusive club in New York

Going from investment banking to running a millwork company is quite the change! Can you walk us through how that happened?

There was a project called Avra in Beverly Hills that my father wasn't going to take because he didn't understand how he would manufacture in New York, deliver out to LA, and manage that job site. I decided it was the right time for me to leave finance to manage this project. I thought, Let's show proof of concept with everything manufactured in New York and delivered to LA. We can take that momentum and keep pushing.

How did your background help with that growth trajectory?

Fabrication shops are usually run by people like my father—more old-school and 60-plus in age. I knew that I could bring different skills to the table. I had my relationships on the banking side, on the design side, on the architecture side. I thought once I got the company to a level that I liked, I would press the gas on those lines of business. So I got in, and I learned. I have always been [around the work], but being in it, I basically had to retrain myself in manufacturing and all the roles. It was a little difficult to hit in the beginning, but once I got my feet wet on the Avra project and started really understanding, I hit a good stride. The company now has around 60-plus employees, and every year we're hitting new growth.

What sets Axos Designs apart from other millwork options out there?

We are hyperattentive to details of scheduling and quality control. Our cabinet makers have very, very keen attention to detail and are able to add value at different points in the process due to their 20-plus years of experience. My father is still involved in a consulting role. His input and guidance [are invaluable because] he's got 30 years of experience; my uncle has 40 years in this trade. The aggregate of that knowledge allows us to answer and attack any situations that arise—while keeping an eye on schedule and design aesthetic.

How do you maintain that personal touch while expanding rapidly?

You have to respect the old world while adapting to the new. This handmade, beautiful craftsmanship is not something I want to reduce—it's something I want to enhance. I want the systems and technology that I incorporate into the process to be an amplifier, a multiplier, of the skill that we can produce, instead of replacing it. The best part about local manufacturing is that I have clients who can come mid-process and touch and feel [the work]. It becomes a really intimate process, and I don't want to lose that level of intimacy and care for the handcrafted.

—Dalene Rovenstine